Neutron Scattering Group Crystal Growth

Crystal Growth

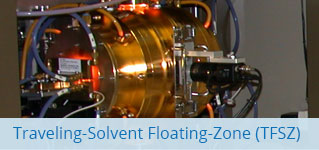

Traveling-Solvent Floating-Zone (TSFZ) method

The expertise of our crystal growth lab is to synthesize large single crystals for neutron scattering experiments. The technique we are using is the so called Traveling-Solvent Floating-Zone (TSFZ) method. The major advantage of this technique is that crystals can be grown without getting into touch with other materials, such as crucibles, which eliminates a major source for contaminations. Currently our lab is operating two image furnaces. With our latest model crystals with high melting point as well as a large length can be grown. The latter is particularly important in the case of incongruent melting systems, where large deviations between the nominal composition and that of the grown crystal are observed in the beginning of the growth experiment.Both image furnaces are equipped with two elliptic mirrors (see figure). As a heat source halogen lamps are installed in the mirrors outer focus. Their light is reflected into the inner focus, which for both mirrors coincides with the location of the melt. The melt is situated between the polycrystalline feed rod (upper shaft) and the grown material (lower shaft), and hold in place by surface tension, only. Feed rod and grown crystal spin in opposite directions to guarantee a homogenous melt as well as a homogenous temperature distribution in the melt. Crystal growth is initiated by a slow downward translation of the feed rod and the lower shaft, which effectively corresponds to a melt traveling along the feed rod. The optimum/maximum growth speed depends on the material and varies between a few tenth of a millimeter and several centimeters per hour. The diameter of the crystal is controlled by the ratio of the translation velocity for the feed rod and the lower shaft. Feed rod, melt and crystal are located within a sealed quartz tube, which allows performing crystal growth in different atmospheres.

Watch a movie of a crystal growth. (.wmv format ~1Mb) or (.mpg format ~5Mb)

Hot Isostatic Press (HIP)

Maximum pressure = 100 kpsi (6.9 kbar), Maximum temperature = 1200 degrees C, Gas = 20% Oxygen + 80% Argon, (1.4 kbar O2 partial pressure), Sample volume = 1 inch diameter, 6 inch highSynthesis and Annealing Program in CMPMSD.