Project Portfolio

Building the sensor array for the world’s largest digital camera

Astronomical surveys have been instrumental in providing data about the universe, from within the reaches of our galaxy and beyond. Over the years, technological upgrades to telescopes have enabled us to detect and image fainter, smaller, and more distant objects in space.

Under construction in Chile, Vera C. Rubin Observatory’s Simonyi Survey Telescope will peer into space like never before. Scanning the visible sky each night for 10 years starting in 2023, the telescope will offer the widest, deepest, and fastest survey of our universe to provide insights into dark matter and energy, the Milky Way, transient objects, and potentially dangerous asteroids.

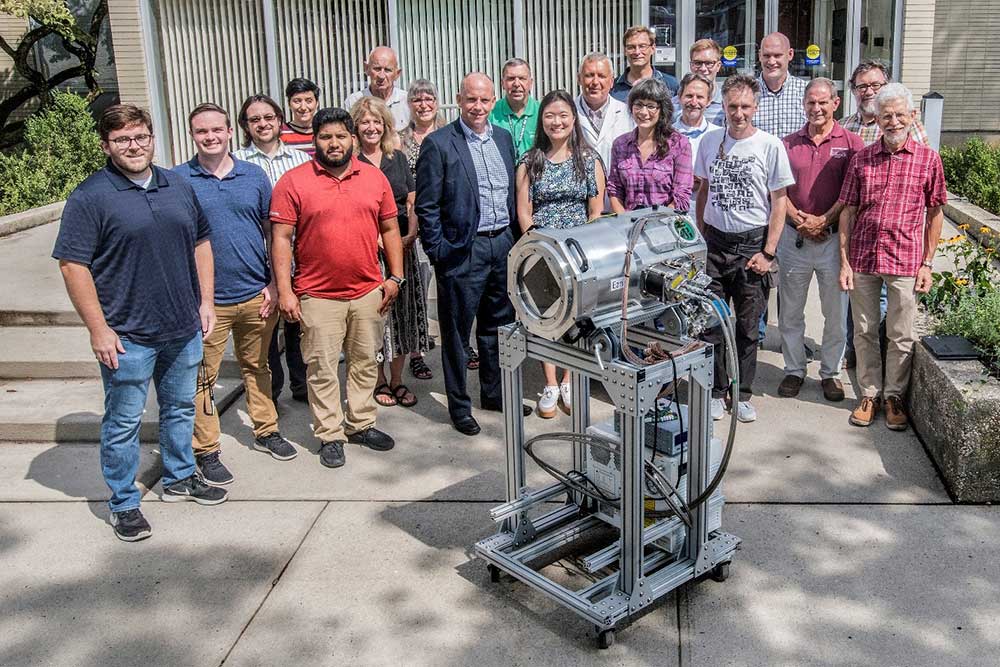

Members of the Brookhaven team with one of the test cryostats used to characterize the behavior of the raft tower module.

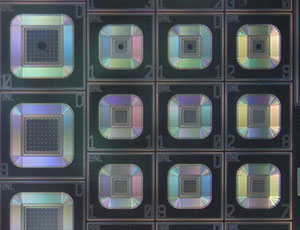

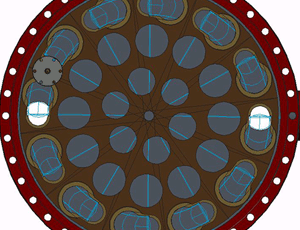

A 3,200-megapixel sensor array will enable the telescope to capture this unprecedented view. For nearly two decades, we have been leaders in the conceptualization, design, construction, and qualification of this sensor array and a complementary electronics readout system.

We began this effort by researching different options for sensor and readout electronic configurations, following an initial set of technical requirements we had drafted in collaboration with government agencies and academic institutions. Under our leadership, a Sensor Working Group produced “strawman” designs for two kinds of sensor implementations: charge-coupled device (CCD) and hybrid complementary metal-oxide semiconductor (CMOS). This early-stage exploration led to the selection of a CCD sensor implementation. We also proposed concepts for optimizing sensor thickness and repurposing science sensors (which take the images) as guide sensors (which help steer the telescope). In collaboration with Harvard University, IN2P3 in Paris, and University of Pennsylvania (UPenn), we advanced the sensor mechanical design and electronics design.

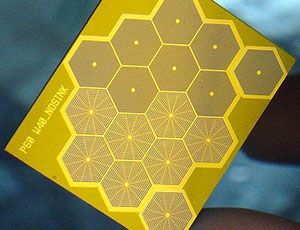

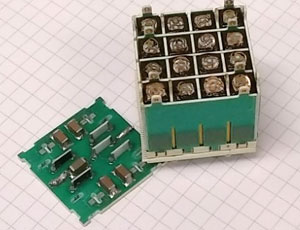

As the technical point of contact for the first round of sensor prototype production, we constructed a cleanroom to evaluate whether vendor prototypes could meet technical specifications. On the readout electronics side, we collaborated with Harvard, IN2P3, and UPenn on an application-specific integrated circuit (ASIC) concept. Together with UPenn and Harvard, we produced prototypes of the readout electronics boards to house this ASIC. Moreover, we provided tailored designs for the detector readout system to enable functions such as digitization, clock and bias generation, and thermal control.

SLAC scientists preparing for a production test of one of Brookhaven’s raft tower modules.

We then devised a plan for integrating a set of nine production-ready sensors with the readout electronics boards into a fully testable, autonomous module. Called the raft tower, this module became the building block for the camera focal plane.

To test the prototype sensors and electronics in an environment close to the expected operating conditions of the final camera, we constructed a laboratory with a specially designed cryostat and optical sources. Here, we performed a “vertical slice test” to characterize the performance of a subscale version of the full system with otherwise final hardware. We also built an optical metrology test station to measure the flatness and coplanarity of the sensors over a range of temperatures (77–200 K). By analyzing the data generated in these test facilities, we validated the mechanical and end-to-end (from incoming photons to outputted digital images) electro-optical performance of the focal plane modules. The equipment, test protocols, and analysis methods served as the basis for Brookhaven’s raft production facility, which was later cloned by SLAC and Rubin Observatory.

Examples from our project portfolio

-

Enabling ultrafast detectors with LGADs

We fabricated the first capacitively coupled (AC) low-gain avalanche diodes (LGADs) based on a new design concept that preserves fast timing capabilities, making these silicon sensors promising candidates for particle tracking in future high-energy physics experiments.

-

Improving energy resolution with SDDs

Our co-invention of the silicon drift detector (SDD) has enabled unsurpassed energy resolution and high count rates for a variety of scientific and industrial applications, including particle physics, astrophysics, mining, and soil surveying.

-

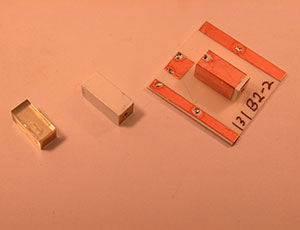

Detecting gamma rays with TlBr

We are developing a detector based on thallium bromide (TlBr)—an emerging semiconductor material with excellent radiation-detection properties—to determine the location and content of radioactive sources that emit gamma rays.

-

Detecting gamma-emitting astrophysical objects with CZT detectors

In support of future astrophysics missions that will probe black holes and other spectacular objects in the universe, we are developing ultrathick cadmium zinc telluride (CZT) detectors with high energy and position resolution.

-

Building the sensor array for the world’s largest digital camera

We have been conceptualizing, designing, constructing, and qualifying the sensor array and electronics for Rubin Observatory’s Simonyi Survey Telescope, which will provide an unprecedented view of the universe.

-

Cooling ion beams with electrons to explore nuclear matter

We fabricated photocathodes for generating electron bunches to cool ion beams at Brookhaven’s Relativistic Heavy Ion Collider. This electron cooling will maximize collision rates, especially at low energies, enabling scientists to explore how nuclear matter exists in different phases.

The Instrumentation Department is part of Brookhaven Laboratory's Discovery Technologies Directorate.