GSI Rapid Cycling Magnets Project

While superconducting magnets easily achieve higher magnetic fields at lower cost than conventional electromagnets, it is very difficult to ramp superconducting magnets very quickly. But exactly that is needed at the planned new facility of GSI, the Gesellschaft für Schwerionenforschung (Institute for Heavy Ion Research), in Darmstadt, Germany. In the magnets of the SIS 200 ring, one of the components of the new facility, the magnetic field must be ramped from 0.5 Tesla to 4 Tesla at a rate of 1 Tesla per second. This ramp rate is almost 25 times faster than the ramp rate of the Relativistic Heavy Ion Collider (RHIC) magnets at Brookhaven National Lab (BNL), which ramp at a rate of 0.042 Tesla per second. While the SIS 200 magnets also require a slightly higher field strength than the RHIC magnets (4 Tesla as compared to 3.45 Tesla), it is the capability to ramp the magnetic field quickly that drives BNL’s research and development work for these superconducting magnets for GSI.

The magnets being developed at BNL for the new GSI facility are based on the RHIC design. However, there are several modifications to reduce ac losses, the unwanted heating of magnet components induced by changing magnetic fields. The by far most significant R&D effort for these fast ramping magnets focuses on the development of a cored Rutherford cable to replace the standard Rutherford cable used in the RHIC magnets.

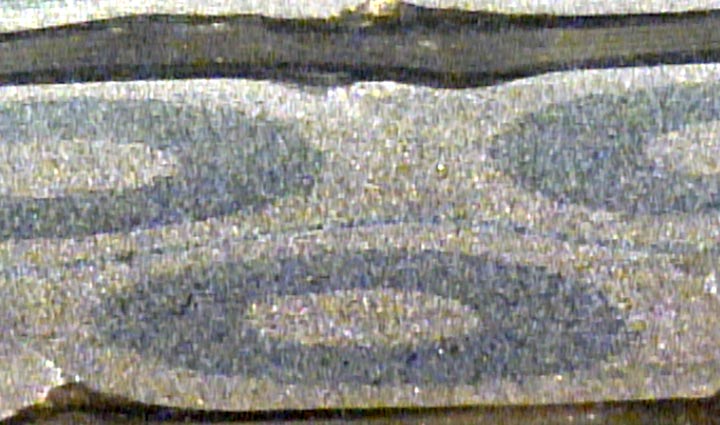

The modified Rutherford cable features a core in the center of the cable that, by increasing the crossover resistance Rc between strands, significantly decreases cable coupling and thus ac losses.

The side view of the cable with the cable edge machined away in the picture to the right shows the foil separating the top and bottom layer of the cable.

Furthermore, a new cabling cooling scheme ensures that the strands of the cable are in intimate contact with the liquid helium coolant.

The holes that are visible in the picture to the right were cut by the University of Jena, Germany. They allow the liquid helium to penetrate into the cable, thus cooling it more efficiently.

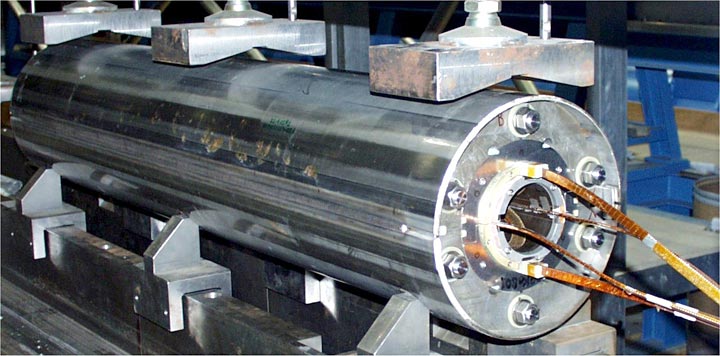

The construction of a first model magnet is completed (see the picture below of the magnet in the shell welding press), and the magnet is awaiting testing.