AUP Quadrupole Magnets for LHC HiLumi Upgrade

DOE laboratories in the United States are working with the European laboratory CERN to build components needed for the High Luminosity (HiLumi) upgrade of the Large Hadron Collider (LHC) in Geneva Switzerland. The principal components to be supplied by the U.S. labs are superconducting quadrupole magnets whose coils are wound with Nb3Sn superconductor. These quadrupoles will be installed in the Insertion Regions (IR) of the LHC, where they will focus the two counter-rotating beams of protons to the smallest possible size at the point where they collide. The magnets will replace the present IR quadrupoles, which have coils wound with NbTi superconductor. Magnets assembled with Nb3Sn coils can produce stronger magnetic fields than those having NbTi coils, allowed a decrease in the size of the beams and, consequently, an increase in the number of collisions (“luminosity”).

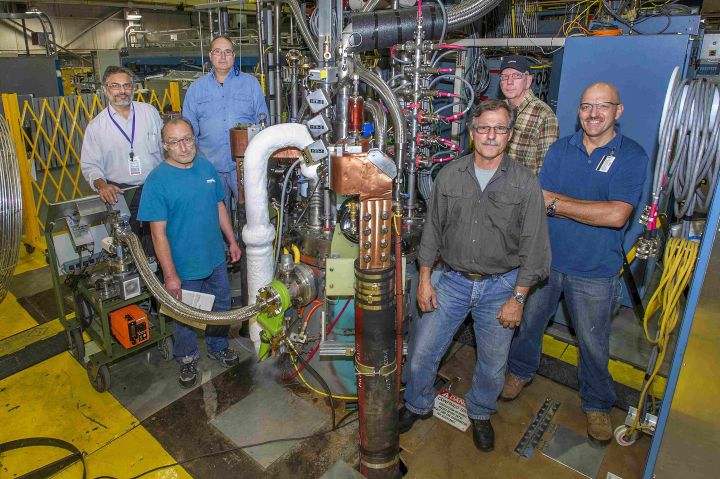

The Superconducting Magnet Division (SMD) staff at BNL is working with colleagues at Fermilab in Chicago and Lawrence Berkeley National Lab in California to build and test the magnets. R&D for these magnets has been underway since 2003, as part of the LARP (LHC Accelerator Research Program) effort. The Mission Need statement (CD-0) for the construction project (HL-LHC Accelerator Upgrade Project) was approved by the Department of Energy in 2015. Deliverables will be ten 8.4 m magnets. Each magnet is composed of two 4.2 m cold masses in a single cryostat. LARP and HL-LHC AUP are led by staff at Fermilab. The LARP website is http://www.uslarp.org.

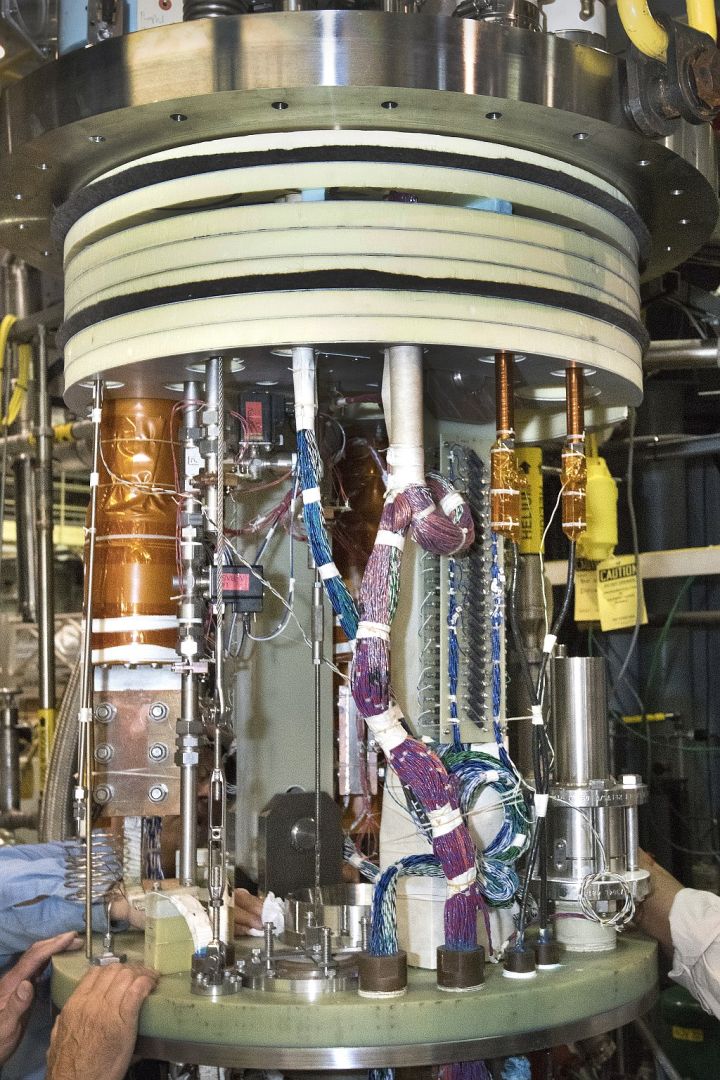

While magnets made with Nb3Sn offer significant performance advantages compared to NbTi magnets, they are much more difficult to make because Nb3Sn must be heated (“reacted”) at 650° C for two days in order for the Nb3Sn to become superconducting. Once reacted, the coils are very brittle, requiring special handling before assembly into magnets. Also, significant development work on the Nb3Sn wire was needed in order to obtain the performance needed for the HiLumi magnets.

The contributions of the SMD staff include development and test of the Nb3Sn wire, coil manufacture, and cryogenic tests of the assembled 4.2 m cold masses in a vertical dewar.

For more information contact Michael Anerella.