Chiral Materials and Unconventional Superconductivity Group

First generation (1G) Bi-Sr-Ca-Cu-O HTS wire development 1986-2000

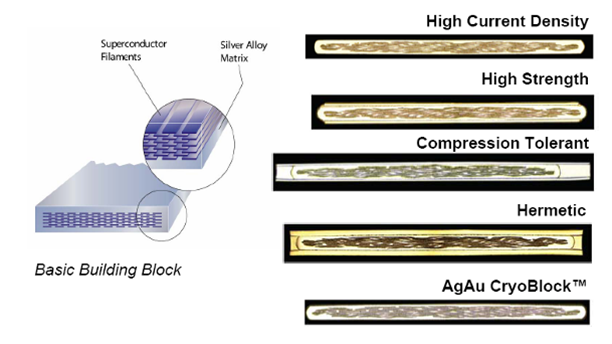

The first-generation (1G) wire is the workhorse of the present-day HTS industry, with many hundreds of kilometres of tape produced for various demonstration projects, primarily power cables and motors. 1G tape is made by packing Bi–Sr–Ca–Cu–O (BSCCO) superconducting powder into a silver tube. BSCCO is a complex oxide superconductor of cuprate family with critical temperature 115 K. Following a series of rolling and heating steps the end product is a 4-mm-wide tape capable of carrying over 100 A at liquid nitrogen temperature and flexible enough to be used in the electric power applications.

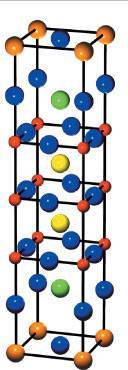

Structure of BSCCO material

Cross-sections of several types of 1G wire produced by the American Superconductor Corporation. The individual strand is 0.2 mm by 4 mm with a critical current of the order of 125 A in zero field at 77 K. White is silver metal; gray is superconductor filament .

1G work at BNL in 1986-2000 relied on a strong Laboratory - industry cooperation that was directed toward the development of practical Bi-2223 superconductor tapes. The relationships among preparation methods, structure, and practical superconducting properties (critical currents) were rigorously investigated. Sample sources included BNL-produced tapes, prototype commercial tapes (SuperPower), and near-production tapes (AmSC).

The early work [1] involved the first X-ray diffraction investigation of intact tapes, using relatively high energy photons at BNL NSLS. The experiment used a unique feature of synchrotron radiation to penetrate the thick layer of silver and obtain structural information about BSCCO core. It was discovered that, in these prototypes, as the texture of the Bi-2223 improves, the critical current tends to increase.

Dependence of critical current density on half-width of (200) reflection in well-textured BSCCO tapes. Data obtained at NSLS beam line X-7A.

The next step was the development of an in situ furnace in which x-ray diffraction could be performed during phase formation [2]. Variations of reaction processes were tested, and effects on reactions, final product structure, and superconducting properties were documented. This knowledge was augmented thorough microstructural and transmission electron diffraction studies on reacted tapes [3].

References

- T. R. Thurston, U. Wildgruber, N. Jisrawi, P. Haldar, M. Suenaga, Y. L. Wang, J. Appl. Phys. 79 (1996) 3122.

- T. R. Thurston, P. Haldar, Y. L. Wang, M. Suenaga, N. M. Jiswari, U. Wildgruber, J. Mater. Res. 12 (1997) 891.

- L-J. Wu, Y-L. Wang, W. Bian, Y. Zhu, T. R. Thurston, R. L. Sabatini, P. Haldar, M. Suenaga, J. Mater. Res. 12 (1997) 3055.