RHIC Project

The Superconducting Magnet Division supplied 1740 magnetic elements, in 888 cryostats, for the RHIC facility at BNL. Of these, 780 magnetic elements were manufactured by Northrop-Grumman (Bethpage, NY) and 360 were made by Everson Electric (Bethlehem, PA). The magnets made in industry used designs developed at BNL. The first cooldown of the magnets for the RHIC engineering run was in 1999. Since then, the magnets have operated very reliably.

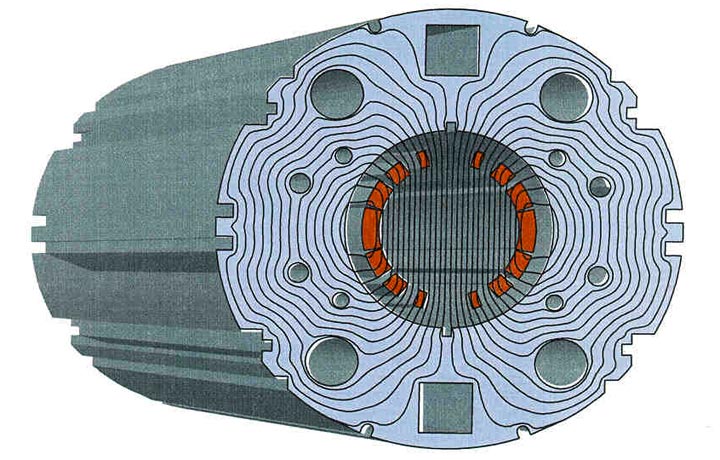

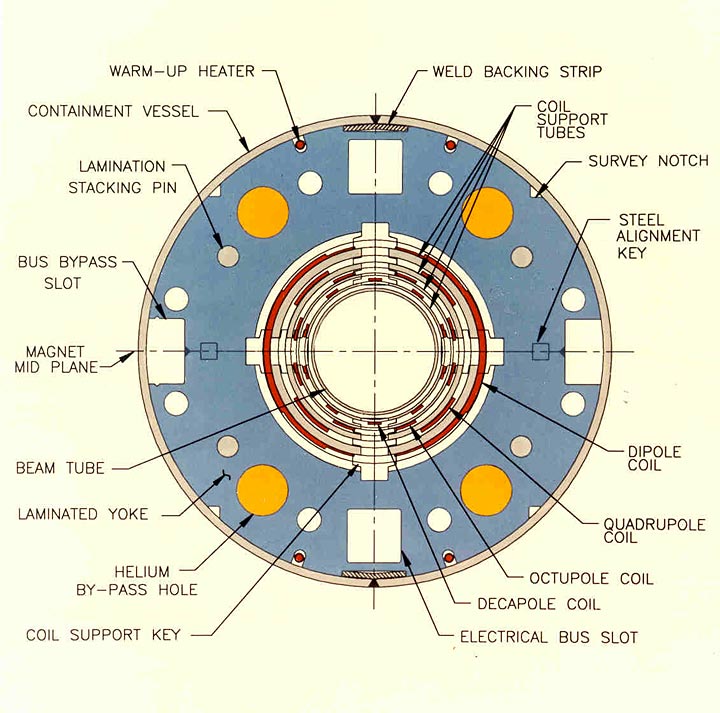

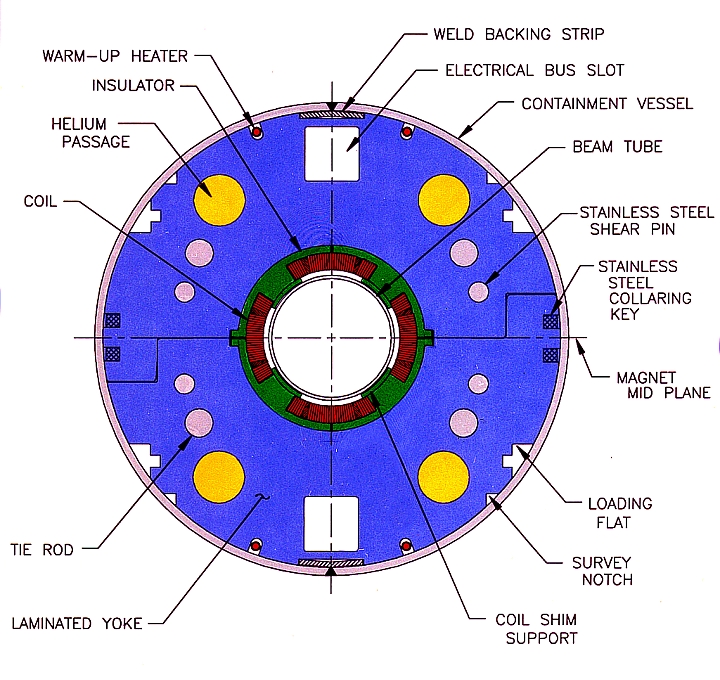

Arc dipole coil and yoke, with magnetic flux lines

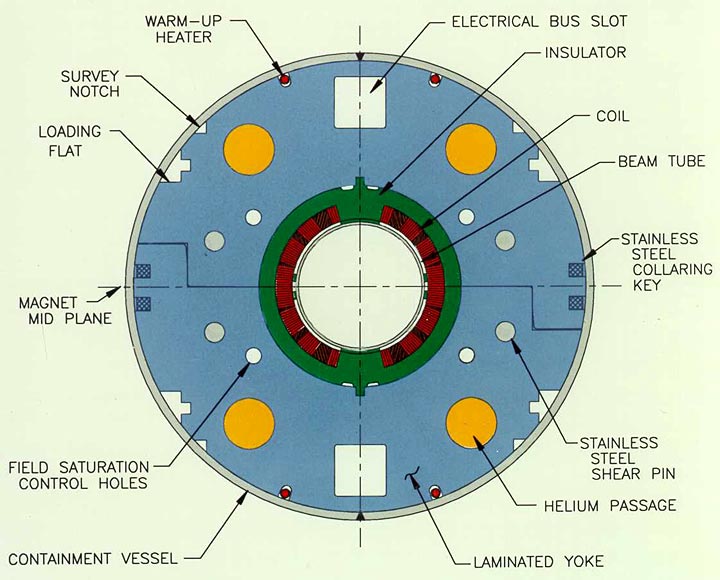

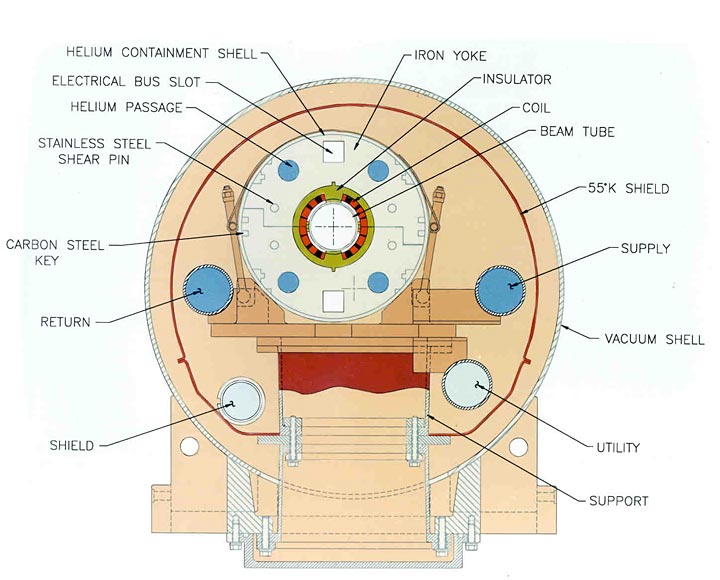

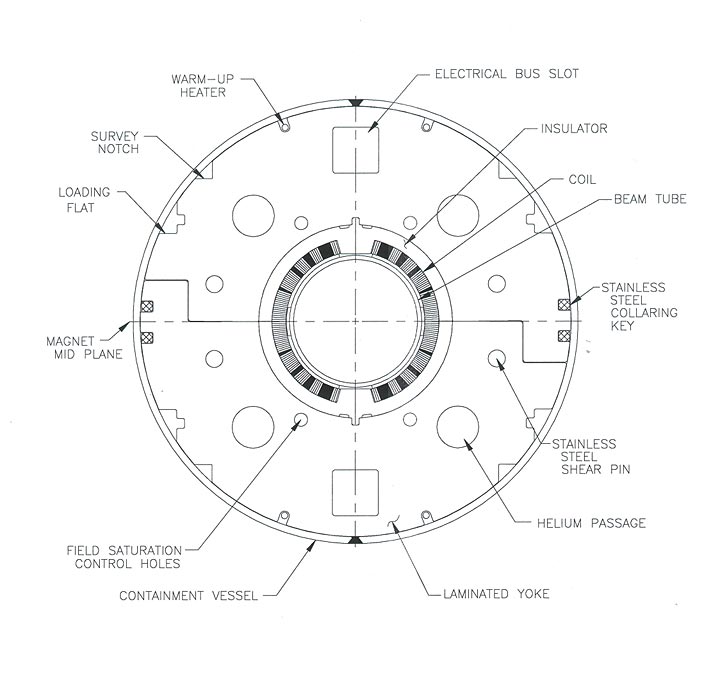

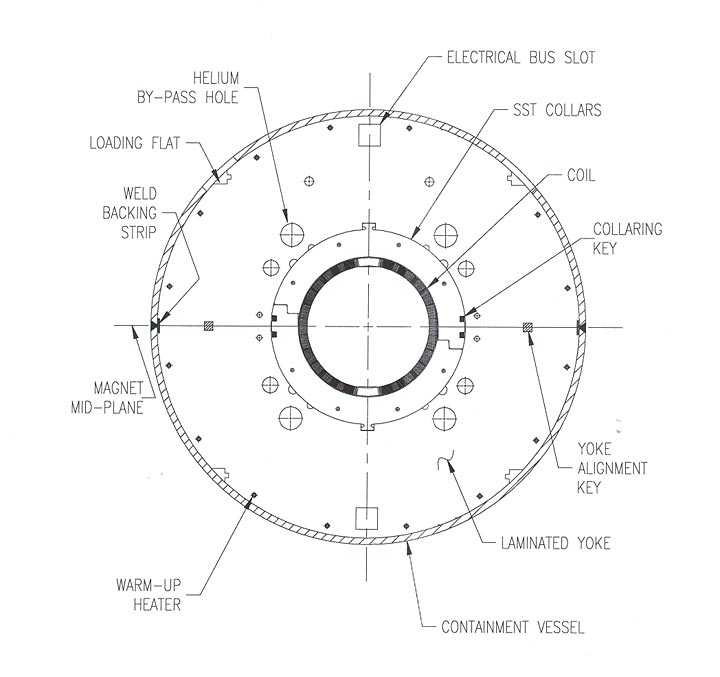

The magnets provide modest field (3.45 Teslas in the arc dipoles) in a cost-effective design. Key features in the principal bending and focusing magnets include the use of NbTi Rutherford cable, a single-layer coil, and cold iron as both yoke and collar. The magnets operate in forced-flow helium at a nominal temperature of 4.6K. The arc dipoles have 8cm aperture and 9.7m length.

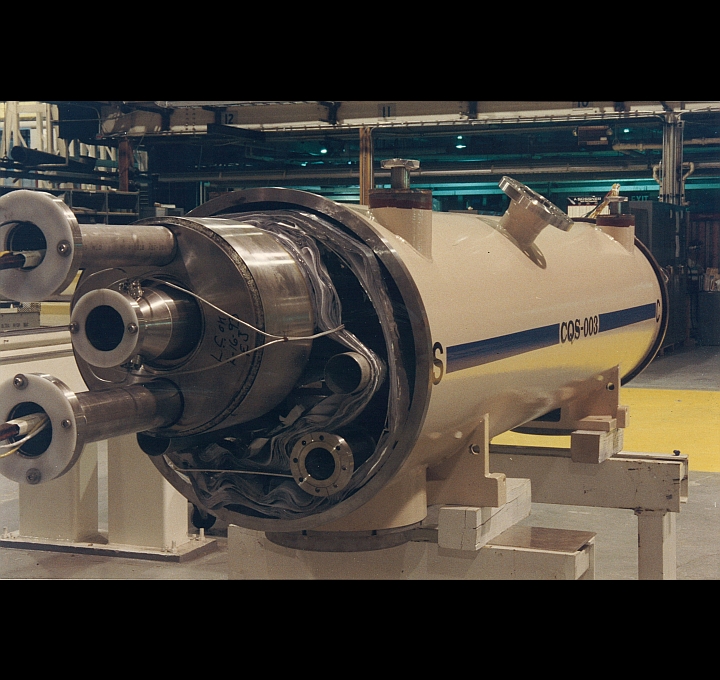

Arc dipole cold mass

Arc dipole magnet

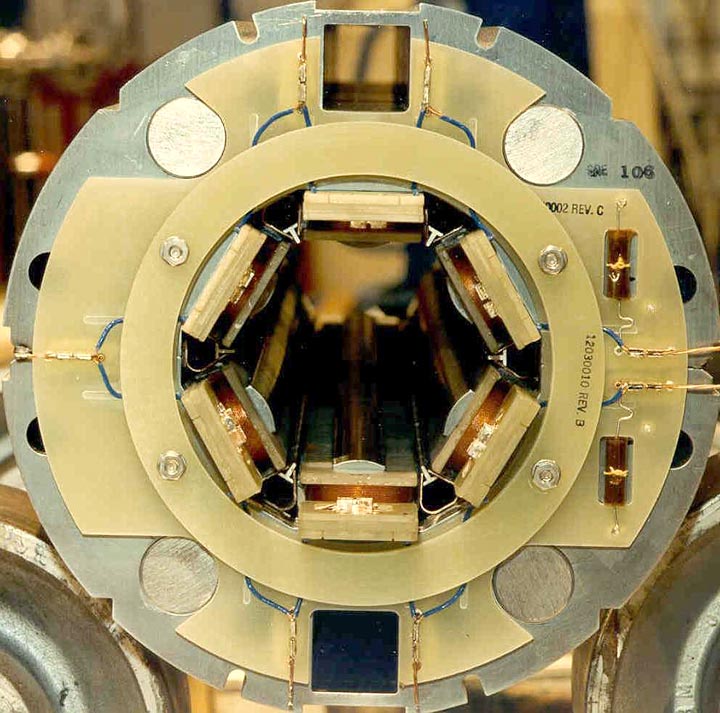

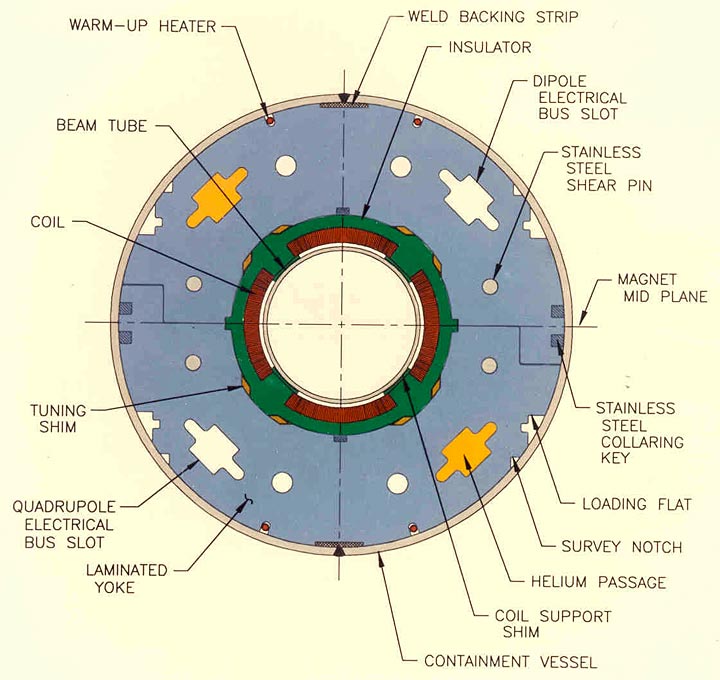

To limit the heat leak at the leads, the coils of the correction elements use a single strand of NbTi wire. The stronger correctors, such as the sextupoles, have a superferric design and modular coils to achieve the needed field strength. The remaining elements, such as the trim dipoles, were made using an integrated CAD-CAM method.

Sextupole

4 layer corrector

The designs of the IR magnets are extensions of those used in the 8cm arc magnets. The 10cm insertion dipoles use the same cable design as the 8 cm dipoles, with a larger yoke. The design of the strand and cable was modified in order to meet the requirements of the 13cm insertion quadrupoles and the 18cm dipoles. Further, to contain the higher Lorentz forces, the coils of the 18cm dipole are clamped both by stainless steel collars and by the yoke. The same manufacturing methods were used for the 13cm correctors as for the 8cm correctors.

D0 cold mass

DX cold mass

IR Quad

Arc Quad Cold Mass

RHIC Corrector-Quadrupole-Sextupole Cold Mass

RHIC Corrector-Quadrupole-Sextupole Magnet

For more information contact Michael Anerella.