Linear Collider Final Focus Magnet Construction

Cable Wound Sextupole

First Pass Winding Tests, R&D Efforts

To further the capability with Direct Wind technology, ongoing tests are being used to develop and determine the range of the process.

Ongoing work will be towards tighter bend radii, as well as reduction of the support tube diameter.

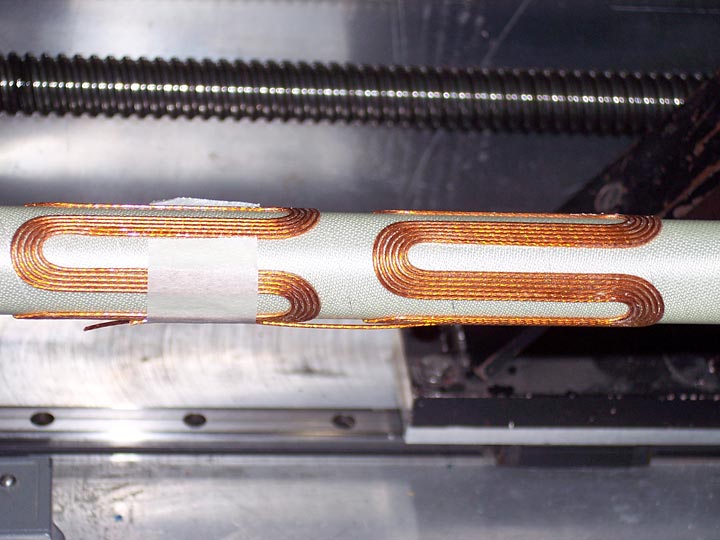

Figure 25 shows the result of refinements to the wiring process. On the left is a sextupole coil wound around a 1 inch diameter support tube. It has five turns in serpentine fashion, this results in a 2.5 turn per pole magnet. On the right is a 6 turn serpentine sextupole. Note that the inner radius, therefore the pole angle, has been reduced, and each pole now has 3 turns equivalent.