Thicker, efficient polymer-based solar cells

November 20, 2017

What is the scientific achievement?

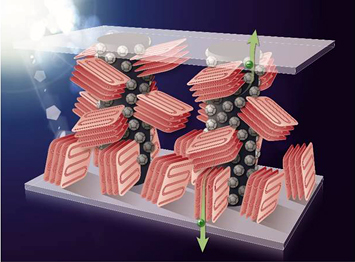

The columnar structure enhances charge mobility in the organic materials, and allows devices to be fabricated more than three times thicker than usual and maintain their performance.

CFN Users from Stony Brook University, working with CFN scientists, demonstrated that adding a third polymer component to the traditional binary mixture of organic solar cell components facilitates self-assembly of a columnar architecture that improves performance.

Why does this achievement matter?

This ternary blend organic solar cell architecture has potential to enable reliable, large-area manufacturing because the devices can be made at thicknesses better suited for conventional coating processes.

What are the details?

enlarge

enlarge

Illustration of a tertiary blend polymer-based solar cell, showing polymer (pink plates) and fullerene (grey spheres) active components, and a third polymer (dark grey columns) that promotes self-assembly of efficient, columnar charge collection pathways (green arrows).

CFN Capabilities:

CFN Materials Synthesis facilities were used to fabricate and characterize the organic solar cells.

Publication Reference

H. Li, Z. Yang, C. Pan, S.K. Satija, D. Xu, D. Gersappe, C.-Y. Nam†, M.H. Rafailovich†, “A new strategy to engineer polymer bulk heterojunction solar cells with thick active layers via self-assembly of tertiary columnar phase,” Nanoscale 9, 11511 (2017).

DOI: 10.1039/C7NR03789A

Acknowledgement of Support

This research was supported in part by NSF-1344267 program. This research was in part carried out at the Center for Functional Nanomaterials (CFN) of Brookhaven National Laboratory (BNL), which is supported by the U.S. Department of Energy, Office of Basic Energy Sciences, under Contract No. DE-SC0012704.

2017-12635 | INT/EXT | Newsroom