Watching oxidation of bimetallic catalysts in 3D

March 13, 2017

What is the scientific achievement?

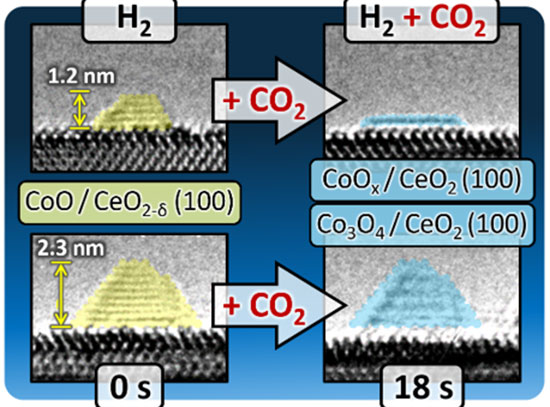

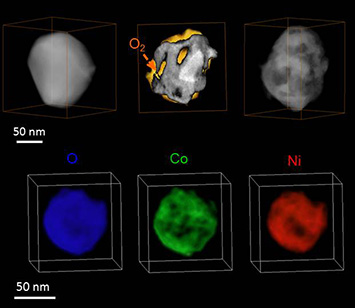

Bimetallic alloy nanoparticles are important catalysts, and understanding the ways they oxidize is key to designing materials for high performance. However, it has been experimentally difficult to observe both the local structure and chemistry during oxidation of multi-component materials. This work combines multiple advanced electron microscopy techniques to reveal the surprising complex ways these materials undergo oxidation on both exterior and interior surfaces.

Why does this achievement matter?

The 3D reconstruction and real-time imaging information reveals the mechanism of bimetallic particle oxidation, which control and alter morphology of hollow structured metal oxides.

What are the details?

enlarge

enlarge

Top Row: 3D evolution of a Ni2Co particle before (left), during (middle) and after (right) oxidation. Bottom Row: 3D mapping of oxygen (blue), cobalt (green), and nickel (red) in a fully oxidized nanoparticle.

CFN Capabilities:

The CFN Electron Microscopy Facility was used for collecting 3D reconstruction data and real-time in-situ and ex-situ images.

Publication Reference

Lili Han1,2, Qingping Meng3, Deli Wang4, Yimei Zhu3, Jie Wang4, Xiwen Du2, Eric A. Stach1, and Huolin L. Xin,1 Interrogation of bimetallic particle oxidation in three dimensions at the nanoscale, Nature Communications 7, 13335 (2016).

10.1038/ncomms13335

BNL press release

BNL social media

DOE Science social media

Other internet media:

Press release: Scientists track chemical and structural evolution of catalytic nanoparticles in 3D

Scientists track chemical, structural evolution of catalytic nanoparticles in 3D

Acknowledgement of Support

This research is supported by the Center for Functional Nanomaterials, which is a U.S. DOE Office of Science Facility, at Brookhaven National Laboratory under Contract No. DE-SC0012704. L. H. was supported by a scholarship from the China Scholarship Council (CSC) (201406250041). Q. M. and Y. Z. were supported by DOE-BES, Materials Sciences and Engineering Division under Contract DESC0012704.

2017-12215 | INT/EXT | Newsroom