A dash of P stabilizes nanocrystalline Ni under stress

September 29, 2017

What is the scientific achievement?

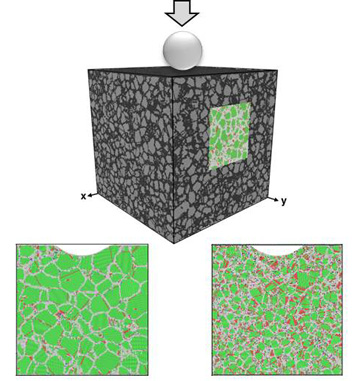

Nanocrystalline metals can be designed to have important technological and engineering properties such as high strength and better wear resistance by incorporating a high density of grain boundaries — although these can also degrade the material stability. CFN users from Stony Brook University studied surface indentations in nanocrystalline nickel by molecular dynamics simulations to understand mechanisms responsible for instabilities under applied stress, finding that addition of phosphorous to the grain boundaries suppresses stress-assisted grain growth.

Why does this achievement matter?

This work identifies a new, fundamental shift in the competition between deformation mechanisms in nanostructured metals, with important implications for the design of new, more stable interface-dominated engineering and structural materials.

What are the details?

Three-dimensional simulation of nanocrystalline nickel under stress. Applied stress causes growth of grains in the nickel structure (lower left), which is eliminated by addition a small amount of phosphorous to the material (lower right). enlarge

enlarge

CFN Capabilities:

CFN Computational Facilities were used to perform the molecular dynamics simulations.

Publication/ Press Release/ Related Links:

Y. Zhang, G.J. Tucker, J.R. Trelewicz, Stress-assisted grain growth in nanocrystalline metals: Grain boundary mediated mechanisms and stabilization through alloying, Acta Materialia 131, 39 (2017).

Acknowledgement of Support

Support for this work was provided through the National Science Foundation under Grant No. DMR-1410941, and DMR-1410970. Results in this paper were obtained using the high-performance Handy and LIRED computing systems through the Institute for Advanced Computational Science at Stony Brook University. The authors also gratefully acknowledge the use of computing resources at the Center for Functional Nanomaterials, which is a US DOE Office of Science Facility at Brookhaven National Laboratory under Contract No. DE-SC0012704.

2017-12543 | INT/EXT | Newsroom