Patterning the Future of Biomineralization with Block Copolymers

April 30, 2024

enlarge

enlarge

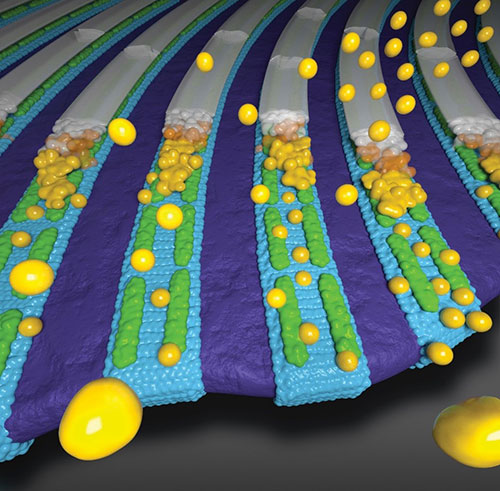

Block copolymer nanopatterns (blue/violet) template assembly of peptide nanoribbons (green), which guide crystallization of calcium phosphate.

Scientific Achievement

Users from the University of Washington collaborated with CFN staff to use block copolymer patterns to facilitate template formation of peptide-based nanostructures, which influence the growth of enamel-like calcium phosphate.

Significance and Impact

Supramolecular templates play a crucial role in directing the growth of biominerals such as tooth enamel. This work provides a potent biomimetic platform to understand such templates.

Research Details

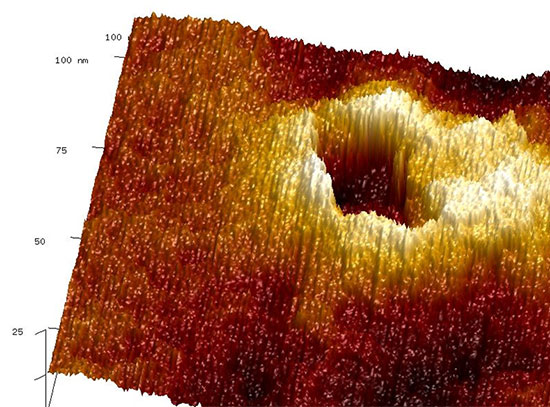

- This work demonstrated how self-assembled block copolymer thin films can serve as chemical patterns, directing the supramolecular self-assembly of amelogenin-derived peptide nanoribbons onto hydrophobic copolymer domains.

- These peptide nanoribbons in turn template the nucleation and formation of filamentous or platelike calcium phosphate.

- This hierarchical platform based on block copolymer directed assembly of supramolecular templates for patterned mineralization mimics the general aspects of mineral growth in functional biological materials such as tooth enamel.

- The research serves as a model system for understanding and designing nanopatterned biomineralization in general, helping to elucidate appropriate nanopattern chemistry, conditions for optimal mineral nucleation, and ideal peptide supramolecular structure.

- Block copolymer hydrophobicity contrast directed peptide nanoribbon assembly, retaining the structure and function that allowed high-fidelity formation of calcium phosphate.

- CFN Materials Synthesis facilities were used to create block copolymer nanopatterns with tunable widths.

Publication Reference

S. Akkineni, G.S. Doerk, C. Shi, B. Jin, S. Zhang, S. Habelitz, J.J. De Yoreo, “Biomimetic Mineral Synthesis by Nanopatterned Supramolecular-Block Copolymer Templates.” Nano Letters 23, 10 (2023).

DOI: 10.1021/acs.nanolett.3c00480

OSTI: www.osti.gov/biblio/1992876

2024 Best Paper Award from the Mineralized Tissue Group (MTG) of International Association for Dental Research (IADR).

Acknowledgment of Support

AFM was performed at the Pacific Northwest National Laboratory (PNNL) and was supported by National Institute of Health/National Institute of Dental and Craniofacial Research (NIH/NIDCR) Grant Nos. RO1-DE025709 and RO1-DE031946. PNNL is a multiprogram National Laboratory operated for the U.S. Department of Energy (DOE) by Battelle under Contract No. DE-AC05-76RL01830. TEM and PiFM were supported by the U.S. DOE, Office of Basic Energy Sciences (BES), Division of Materials Science and Engineering (MSE) under Award No. FWP 65357 at PNNL. TEM was performed on a project award (67554) from the Environmental Molecular Sciences Laboratory, a DOE Office of Science User Facility sponsored by the Biological and Environmental Research program under Contract No. DEAC05- 76RL01830. PiFM was performed at the Molecular Analysis Facility, a National Nanotechnology Coordinated Infrastructure (NNCI) site at the University of Washington, which is supported in part by funds from the National Science Foundation (Award Nos. NNCI-2025489 and NNCI-1542101), the Molecular Engineering & Sciences Institute, and the Clean Energy Institute. Patterned BCP substrates were synthesized at the Materials Synthesis and Characterization facility of the Center for Functional Nanomaterials (CFN), which is a U.S. DOE Office of Science User Facility at Brookhaven National Laboratory (BNL) under Contract No. DE-SC0012704. We also thank Ashley Head (BNL) for assistance with preliminary IRRAS measurements on BCPs and Yushi Bai for assistance on PILP solution recipe. Funding Sources: S.A., J.J.D., and S.H. were supported by NIH/NIDCRGrant Nos. RO1-DE025709 and RO1-DE031946; C.S., B.J., and S.Z. were supported by the U.S. DOE, BES MSE under Award No. FWP 65357 at PNNL.

2024-21896 | INT/EXT | Newsroom