Solvent Vapor Takes Nanopore Fabrication to New Heights

October 22, 2024

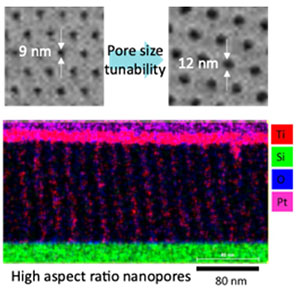

Substrate functionalization, automated SVA, and homopolymer blending enable self-assembly of well-ordered vertical nanopore arrays with tunable sizes.

Scientific Achievement

CFN and Columbia researchers developed a robust protocol for fabricating highly ordered arrays of vertical nanopores in thin films using the self-assembly of a block copolymer (BCP) and solvent vapor annealing (SVA).

Significance and Impact

This method enables precise control over nanopore dimensions and orientation, with potential applications in nanolithography, membrane filtration, and energy storage.

Research Details

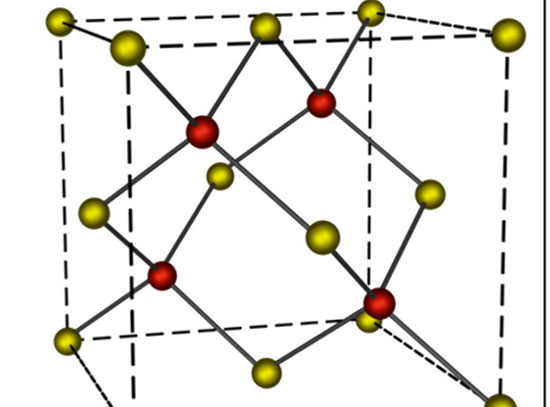

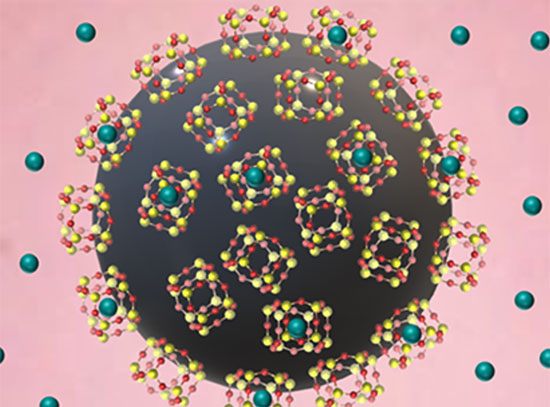

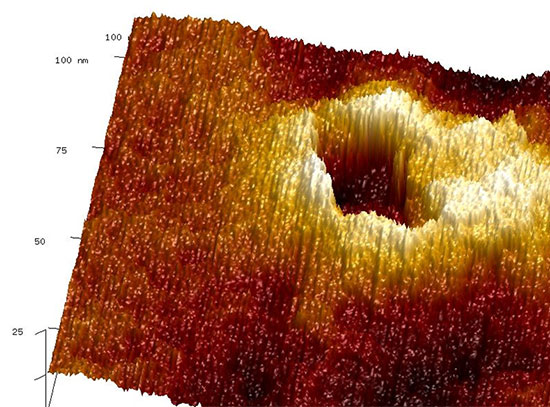

Utilizing the self-assembly of block copolymers with large Flory-Huggins interaction parameters (χ) for nanofabrication is a formidable challenge due to the large surface energy differences between the blocks. This work reports a robust protocol for the fabrication of highly-ordered, vertical cylindrical nanopore arrays with tunable diameters via the self-assembly of a poly(styrene-block-4-vinyl pyridine) (PS-b-P4VP) diblock copolymer blended P4VP homopolymer. The desired vertical orientation is achieved by automated, feedback-controlled solvent vapor annealing (SVA) using acetone, a weakly PS-selective solvent, and functionalizing the substrate with a surface-grafted poly(2-vinylpyridine) (P2VP) homopolymer. Crucially, we reveal that nonselective swelling by the surface-grafted homopolymer is essential to stabilizing the vertical orientation. We further characterize pore formation by addition of P4VP homopolymer and its post-assembly extraction using ethanol, delineating homopolymer molecular weights and volume fractions that maximize the range of pore available diameters while maintaining vertical orientations. This study outlines key design rules for using high χ block copolymers to fabricate high-aspect ratio vertical nanopores with sub-10 nm diameters for applications in cutting-edge nanolithography, energy storage, or precision ultrafiltration.

- The study blended a poly(styrene-block-4-vinylpyridine) BCP with a homopolymer and applied automated SVA and substrate functionalization to vertically orient cylindrical nanopores.

- The size of high aspect ratio nanopores can be finely tuned by adjusting homopolymer composition.

Publication Reference

B. Bellini, J.R. Willard, S. Cetindag, E.H.R. Tsai, R. Li, K. Kisslinger, S.K. Kumar, G. S. Doerk, “Assembling Vertical Block Copolymer Nanopores via Solvent Vapor Annealing on Homopolymer Functionalized Substrates”, ACS Applied Materials and Interfaces, 16, 35541-35553 (2024).

DOI: https://doi.org/10.1021/acsami.4c05715

OSTI: https://www.osti.gov/biblio/2382648

Acknowledgment of Support

This research used the Materials Synthesis and Characterization facility, the Electron Microscopy facility and the X-ray scattering partner user program at the Center for Functional Nanomaterials (CFN) and the 11-BM end station of the National Synchrotron Light Source II (NSLS-II), which are U.S. Department of Energy (DOE) Office of Science User Facilities, at Brookhaven National Laboratory under Contract No. DE-SC0012704. S.C., B.B., and G.S.D. were supported by a DOE Early Career Research Program grant.

2024-22178 | INT/EXT | Newsroom